Contact Details:

Wheelabrator

1606 Executive Drive

LaGrange

GA

30240

United States of America

Tel: +1 706 884-6884

Fax: +1 706 884-0568

Send Enquiry | Company Information

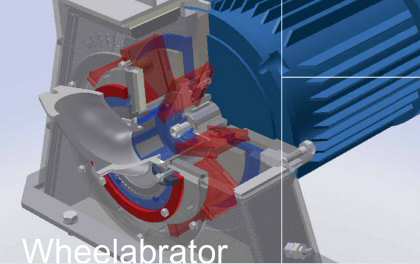

EZEFIT® Wheel Family Brochure

Product News Monday, July 23, 2007: Wheelabrator

Wheelabrator Produces New Brochure for EZEFIT® Wheel Family

The EZEFIT® Wheel Family product brochure is devoted to the latest Wheelabrator Group specialized wheel design for optimal performance in the surface preparation industry.

This extensive Wheelabrator® wheel line is available for Original Equipment Manufacturers (OEM) and Equipment Modernization Programs (EMP). It includes wheels for all types of applications, including the POD EZEFIT, EZEFIT Pivot, Upblast EZEFIT and Blast-Lite™. Additionally, the EZEFIT wheels are available in various wheel blade widths, for customized solutions for difficult process issues.

Wheelabrator customers have experienced 25 to 40 percent reductions in blast cycle time and cut replacement costs on parts by 30 to 50 percent with EZEFIT wheels. Replacement parts inventory is also reduced due to longer part wear life and shorter lead time on replacement parts. Additionally, EZEFIT wheels are easier to assemble and take apart, allowing for a 50 percent reduction time when changing an EZEFIT wheel tune-up kit when compared to other wheel systems.

EZEFIT wheels offer the inherent advantage of bi-directional rotation and can lower replacement parts inventory through the ability to serve clockwise or counterclockwise wheel applications with a single style wheel. Wheelabrator has capitalized on this advantage with a direct-drive design that offers standard or custom base mounting for increased versatility. EZEFIT wheels are available in 3-1/2” or 2-1/2” blade widths. 3600 RPM and 1800 RPM versions are offered in a variety of wheel diameters.

In addition, Wheelabrator Plus offers an Equipment Modernization Program (EMP) for wheel blast equipment. The technological advancements made by Wheelabrator Group research and development personnel are available for non-Wheelabrator equipment. By upgrading to new wheel blast technology, users will benefit from many positive results, including reduced operating costs, minimized machine down time, improved manufacturing efficiency and reduced maintenance time costs.