Contact Details:

IAC - Industrial Automation & Control (Pty) Ltd

Communica Building

53 Landmarks Avenue

Samrand Park

Centurion

Gauteng

0157

South Africa

Tel: +27 (0)12 657 3600

Fax: +27 (0)12 657 3630

Send Enquiry | Company Information

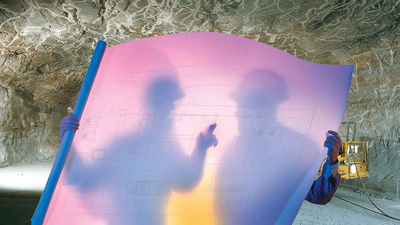

Hirschmann Sends All the Right Signals — From the Control Room to Underground Mining Stations

Product News Thursday, February 14, 2013: IAC - Industrial Automation & Control (Pty) Ltd

Hirschmann Sends All the Right Signals — From the Control Room to Underground Mining Stations — and Everywhere in Between

Mines often have multiple mining sites and underground mining operations, so the breadth of the information monitoring problem can be rather extensive and complicated. Actual mining is done several kilometres from the control room and therefore communication has to be fast and effective to make certain that information is readily available to ensure that the control room on the surface has complete access to every activity inside the mine. Furthermore all of the mine equipment and environmental information need to be available without interruption in order to support operating decisions and to avoid compromising safety. Mining sites operate around the clock and breakdown or communication failure is not allowed. Maximum productivity with minimal downtime is a key goal, and 24/7 network performance and reliability are critical to achieving that goal. If a network switch, connector or cabling system fails, the cost of parts replacement and repair represents only a tiny fraction of the overall costs associated with production downtime – it will quite possibly mean unplanned downtime, an increased risk of recurring repairs, and a lowering of the level of safety in the mine. Real-time data streaming, monitoring and communication is of upmost importance to ensure high standards of safety and avoiding tragic accidents underground. These tasks and needs are difficult to deal with without reliable industrial networking devices.

Mining however remains one of the most challenging industries for industrial networking. When active device and media installations operate in these severe environmental conditions underground, networking devices must endure the destructive effects of dust, dirt, dampness and corrosion, threatening equipment and performance. In some mines, caustic chemicals and potentially explosive ambient conditions exacerbate the threat. These stressors can wreak havoc on the mission-critical networks tasked with conveying signals between measuring instruments and control devices. Given these environmental risks, it only make sense that you need industrial network instrumentation that are designed, manufactured and tested for especially harsh or mission-critical environments, to meet the strict safety regulations imposed by the mining industry. Any physical deterioration or failure in key components can lead to unreliable network performance and/or safety issues, and may ultimately lead to loss of critical data, costly downtime, or even catastrophic failure.

Another factor to consider for mission-critical applications is redundancy, which is extremely important but sometimes overlooked in selecting industrial Ethernet switches. Two specific kinds of redundancy are key to maintaining uninterrupted signal transmission and maximum uptime:

Power source redundancy - Having an uninterruptible power source (UPS) is absolutely critical to consistent and reliable switch performance. Specifying switches that have dual power input capabilities means that if one power source fails, the other immediately takes over.

Data path redundancy - The daisy-chain network topologies used by many industrial plants to connect automated machinery and devices have one inherent flaw: if any link between the two switches fails, the entire system could potentially go down, as the devices on one network segment can no longer communicate with devices in other segments. The solution is to build in a redundant data path which can take the form of either a ring or mesh topology.

The Hirschmann product family meets and exceeds all these requirements as they are manufactured to comply with the applicable standards of the mining industry, effectively eliminating network downtime inside the mine and ensuring a superior performance in safety and production. All Hirschmann networking products have been designed with full redundancy and data is transmitted between the controllers and the remote I/O stations via fail-safe redundant optical fibers. Hirschmann’s highly reliable industrial-grade solutions keeps information flowing at all times, streaming data about the status of workers, equipment and safe working conditions. The Hirschmann (a Belden Brand) portfolio extends from a comprehensive range of cables and connectors, through rugged Ethernet switches, to routers and firewalls – all Hirschmann products are subjected to the stresses you encounter in the form of electro-magnetic interferences, high-operating temperatures, and mechanical stresses.

For more information, contact Raine Sadie, IAC (Pty) Ltd, +27 (0)12 657 3600, raine@iacontrol.co.za