Contact Details:

Vepac Electronics

13 Eighth Avenue

Edenvale

Gauteng

1610

South Africa

Tel: +27 (0)11 453 1910

Fax: +27 (0)11 453 7751

Send Enquiry | Company Information

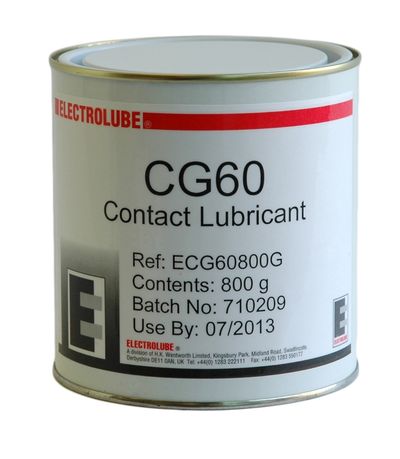

Contact Grease

Product News Thursday, December 8, 2011: Vepac Electronics

Contact Grease 2G

Product Description

The Electrolube number 2 range of contact lubricants were developed in response to a requirement for an effective treatment for all types of contacts, particularly in situations where extremes of temperature and environmental conditions are encountered. Correct application of the right grade will reduce contact resistance and arcing of contacts of all ratings from small relays to high capacity contactors.

This range includes SGA contact grease, SOA contact oil and SFA dilute contact oil. SGA is a non-melting grease which will not migrate from vertical contacts or surfaces and will provide greater protection from atmospheric conditions than an oil.

Electrolube have additional contact grease products with different properties for specific applications. These include improved plastics compatibility, wider temperature range etc. Please ask for further details.

Features

• Effective at low temperature (-40°C).

• Low evaporative loss (0.4% after 72 hours at 100°C).

• Contains no silicones.

• Excellent lubrication properties (spiral shaped molecules with effective length of 20 Angstrom units).

• Will loosen tarnish and corrosion and leave a protective film to prevent further contamination.

• High stable synthetic material, fully inhibited against copper corrosion, oxidation, etc.

• Improves contact performance by increasing the effective contact area and preventing arcing.

Typical Product Applications

SGA is suitable for use on all types of electrical contacts including those in corrosive industrial environments and in heavy arcing conditions e.g. large connections, battery terminals, contactors, busbars, knife switches, rheostats, large voltage regulators etc.

SGA may also be used on fixed or moving contacts, edge connectors, turret tuners, plug sockets, switching devices, potentiometers, fuses, small regulators, slip rings, slider/rotary controls, rocker/push-pull edge connectors, valve pins, switchgear and butting contacts.

Care should be taken to ensure that certain paints, rubbers, and thermoplastics are not near the area of the contact. A small area should be tested first to ensure compatibility.