Contact Details:

GEA Africa (Pty) Ltd

Corporate Park South

48 Reedbuck Crescent

Midrand

Johannesburg

South Africa

1985

South Africa

Tel: +27 (0)11 392 7114

Alt. Tel: +27 82 550 7951

Send Enquiry | Company Information

GEA demonstrates excellence in food processing at IPPE 2019

Product News Wednesday, December 12, 2018: GEA Africa (Pty) Ltd

Key highlights include its new multi-purpose brine injector, the GEA MultiJector 2mm with flexible needles; the new GEA CookStar with in-line smoking application for super heat smoke; a new decanter series, GEA ecoforce for processing high quality animal by-products and a new packaging machine PowerPak PLUS. The new unique in-line freezer control system CALLIFREEZE®, which was launched during Anuga FoodTec 2018 in Germany, will now be presented to the North American market.

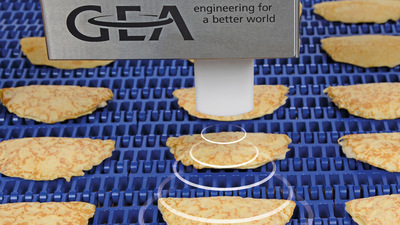

GEA MultiJector for high quality bacon and poultry production

As inventor of industrial injection, GEA will celebrate its 50 years of expertise by introducing the new MultiJector 2mm, an innovative continuous in-line injection solution developed for high quality and accuracy in the art of bacon making and poultry processing. The new equipment features unrivaled injection accuracy with a low standard deviation for excellent product quality and maximum profitability; flexible needles that will not break or distort, and maximum Time-in-Meat technique. The modular design includes exchangeable manifold needle cassettes for easy cleaning and quick changeover.

Time-in-Meat is a GEA injection precision technique based on the specific combination of stroke height and injection cycle time, both optimized for each product type. Thanks to the Time-in-Meat technique, the needles stay in the product longer during injection, which leads to better brine uptake and more even brine distribution. As a result, product quality and consistency are significantly increased, and higher efficiency and yields can be achieved.

At the heart of the GEA MultiJector are the unique 2mm OptiFlex needles which combine flexibility with special strength. They are four times stronger than traditional stainless steel and will flex and recover their shape, helping to prevent bent or broken needles and ensure consistent quality and maximum productivity. This help avoid over or under-cured areas for a more consistent taste and color.