Contact Details:

Dymot Engineering Co. (Pty) Ltd.

11 Derrick Road

Spartan

Kempton Park

Gauteng

South Africa

Tel: +27 (0)11 970-1920

Fax: +27 (0)11 970-1979

Send Enquiry | Company Information

USEFULL INFORMATION FOR WINCHING APPLICATIONS

Product News Monday, March 6, 2017: Dymot Engineering Co. (Pty) Ltd.

There are several factors that need to be taken into account to achieve proper rope lay on a winch drum and rope life. Of these factors the most important is the magnitude of the D/d ratio (Drum/Sheave to Rope Diameter) and the fleet angle.

BENDING RATIO OF ROPE (D/d)

When the wire is bent, over a winch drum, a tensile load is subjected to the outer fibres of the rope.

The magnitude of these tensile stresses is inversely proportional to the radius of the bend.

Thus the larger the radius is the lesser the stresses will be.

TABLE 1 depicts the recommended minimum drum and sheave diameters in terms of the rope diameters for various rope constructions. These values are the minimum values when working on a single layer of rope and for speeds below 1 m/s. An addition of 5% should be added to the recommended diameter with every 0.5m/s increase in speed above 1m/s.

ROPE CONSTRUCTION

MINIMUM RECOMMENDED DRUM AND SHEAVE DIAMETERS

6 x 19 (9/9/1) F or IWRC

28 x Rope Diameter

6 x 25 (12/6 F+6/1) F or IWRC

23 x Rope Diameter

6 x 36 (14/7+7/7/1) F or IWRC

19 x Rope Diameter

6 x 41 (16/8+8/8/1) F or IWRC

18 x Rope Diameter

6 x 43 (14/14/7F+7/1) or IWRC

18 x Rope Diameter

6 x 49 (16/8+8/8/8/1) IWRC

18 x Rope Diameter

15 Strand N/S 9x6/6x19(9/9/1)IWRC

26 x Rope Diameter

18 Strand N/S 12x7(6/1)/6x7(6/1) F or IWRC

26 x Rope Diameter

18 Strand N/S 12x9(9/9/1)/6x19(9/9/1) F or IWRC

24 x Rope Diameter

8x25 (12/6F+6/1) IWRC Spin Reduced

19 x Rope Diameter

6x13(7/6Δ)F

42 x Rope Diameter

6x30(12/12/6Δ)F

42 x Rope Diameter

TABLE 1: The minimum recommended ratio of rope to drum and sheave diameters at < 1m/s.

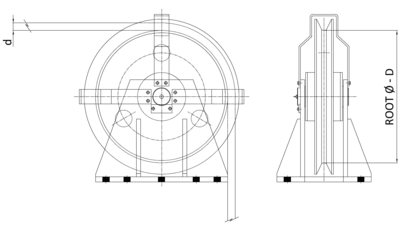

In situations where the rope will only work intermittently the drum and sheave diameters can be reduced by as much as 25% from the recommended minimum values as listed in TABLE 1. Further reduction from this is not recommended under any circumstances as this will result in severe increase in bending stresses and will result in rapid rope fatigue. Please see FIGURE 1 for Illustration of D/d.

Dymot is involved with the majority of Mining Projects and have products in more than 40 countries.

For more information please contact us on 011 970 1920 or visit our website at www.dymot.co.za .

Jorick Snyman – Mechanical Engineer – Dymot Engineering Company