Contact Details:

Brubin Pumps: A Part of Torre Industries

11 Avalon road

Westlake view Ext 11

Modderfontein

Gauteng

1610

South Africa

Tel: +27 11 923 7000

Send Enquiry | Company Information

Brubin pumps brings innovation to Electra Mining 2016

Company News Thursday, September 8, 2016: Brubin Pumps: A Part of Torre Industries

With substantial developments underway, Brubin pumps, which forms part of the Letaba pumps, will be showcasing a number of innovative products at Electra Mining 2016 in Hall 6, stand K12.

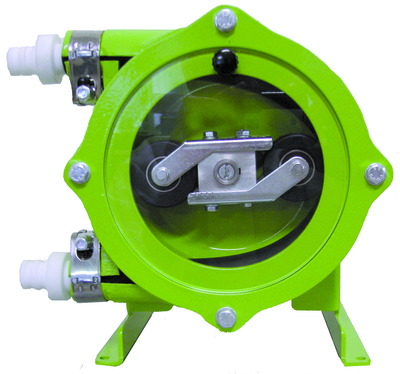

One such innovation being displayed is the Brubin BA CIP (Cleaning in Process) Hose Pump. A stainless steel (40mml) working model of this pump will be displayed at Hall 6, Stand K12, making it a first for South African audiences.

“So far, the international success of this pump design has seen over €1m being secured in investment,” says Brubin General Manager, Hannes Liebenberg, who highlights that the pump can be dually used in the General Industry as well as Mining Industry for In Process cleaning. These pumps use a collapsible shoe technology, which opens the hose for in process cleaning.

Pumping action is achieved by compression of a circular loop of elastomeric hose with two diametrically opposed rotating shoes. The rotational motion forces fluid in the hose to move ahead of each shoe. When each shoe reaches the end of the loop, the reinforced tube immediately returns to its immediate shape, thereby ensuring suction and priming. The pump housing is partially filled with lubricant, aiding in smooth running of the shoes on the hose. Because the inside of the hose and inserts are the only parts in contact with fluid, aggressive and contaminated fluids can be pumped. With the CIP Technology these fluids can be successfully flushed.

The moment the shoes are reversed, they collapse, which opens up the entire hose. The hose stays in that position until it is reset. “By opening the hose completely, air or water can pass through easily, making the hose easy to clean,” says Liebenberg.

On a standard pump, users would have to open the unit completely for cleaning, which takes about 8 hours on a large pump. “This new design saves time, since users do not need to open up, pull apart, or drain the pump as with the standard hose pump design.

Despite this, some people have suggested that this concept presents difficulties because there are too many moving parts. However, this is not the case, says Liebenberg. “This pump is purely for peristaltic purposes, and will never fail”.

Meanwhile, another innovation from Brubin will be showcased at Electra Mining. “The Brubin Magnetic Drive Pumps (Mag Drives) are the future of chemical pumping,” says Letaba Pumps MD, John Vass, who highlights the importance of this innovation within the global green movement, as well as its place at Electra Mining. “Our Brubin Mag Drives are being supplied to the likes of Denel and Sasol because of their reliability and international support,” says Liebenberg.

The Brubin range of Mag Drives is built in South Africa, and has an already impressive footprint in the industry. “I believe these represent the future of pumping when it comes to clear acids. In the USA, over 50% of clear acid applications use Mag Drives. Despite this, some industry players don’t seem to appreciate the environmental issues faced with leakages,” says John. He highlights that Mag Drives don’t use mechanical seals or Gland Packing and there is no danger of a leak.

The Magnetic Drive Pumps are supported by well-known international manufacturers.

For more information, contact:

Mbali Msimango

+27 (0)11 9237000

+27 (0)72 562 2980

mbali@torreindustries.com