Contact Details:

Tasol Solar (Solar Academy of Sub Saharan Africa (Pty) Ltd)

6 Vereeniging Street

Alrode

Alberton

Gauteng

South Africa

Tel: +27 (0)86 111 3078

Fax: +27 (0)86 613 8308

Send Enquiry | Company Information

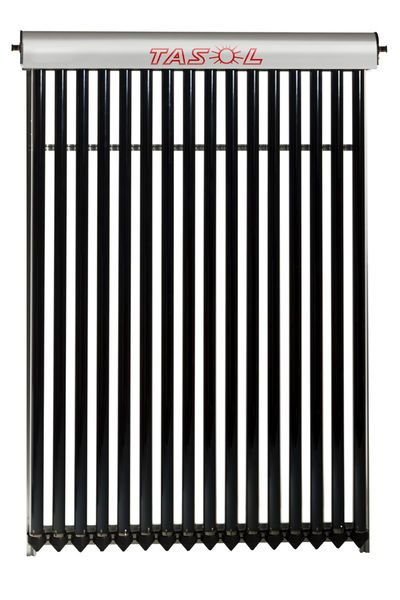

Freeze Resistant Solar Water Heating Collectors

Product News Tuesday, November 23, 2010: Tasol Solar (Solar Academy of Sub Saharan Africa (Pty) Ltd)

South Africa has recently experienced one of the coldest winters in 5 years, and many questions have been raised within the industry regarding the freeze resistance of solar water heating systems. An article in the consumer watch section of The Star dated 28 June 2010 reported on the damage of some flat plate collectors installed as direct systems. Although Tasol supports both the Flat Plate and Evacuated tube technologies, it is important to recognize the differences.

Why do some collectors freeze?

Water has the anomalous behavior that it shrinks as it cools down, but expands when its temperature goes below 4 degrees Celsius with further cooling. This is the direct cause for water pipes bursting as a result of this volumetric expansion. The Tasol Heat Pipe Evacuated Tube collectors have a “free flow” concept through the manifold section of the collector. This section is very well insulated with a thick layer of compressed Rock Wool.

Tasol uses Evacuated Tube Technology (EVT) in both our direct high pressure and low pressure solar water heating systems.

To date Tasol have installed 4647 direct EVT (Evacuated Tube Technology) high pressure solar water heating systems in non coastal regions (Gauteng , Free State, Mpumalanga, Northern Cape, North West, Polokwane and Non Coastal areas of the Eastern Cape) and we have not received one report on EVT collector damage or failure!

How it works:

An array of evacuated tubes joined to a manifold, through which the heat transfer fluid flows. Tubes usually have heat pipes in the center of the glass tube which transfers the collected heat to the manifold.

Heat loss is greatly reduced due to space between the absorber area and the glass outer wall by evacuating the air from the cavity. There is therefore little air to move and transfer of heat by conduction and convection. Heat is not transferred through a vacuum.

The anti reflecting coating further prohibits the irradiation of heat from the collector. The top section of the collector, where the heat pipes join in a manifold, is completely filled with polyurethane which is an excellent insulator.

At the bottom of the collector tubes, there are barium coated sections to maintain the vacuum through a gettering process. This means that any air molecules, formed by out gassing, will be absorbed by the barium.

All the copper plumbing to the manifold is protected by insulating material with an R value>1 as well as extra protection for the first meter of pipe joining the manifold, by means of a silicone insert. This insert is a sealed unit with imbedded air pockets to take up any volumetric expansion during the freezing process within the copper pipes. The exposed parts of the solar system are therefore protected fully from harshly cold environments.

Contact Prof. Ronnie Mulder on 083 470 1901 for more information.